How AI and Automation Are Shaping the Future of MRO Management

- Dec 9, 2025

- 6 min read

Updated: Jan 15

Introduction: A New Era for Aviation Maintenance

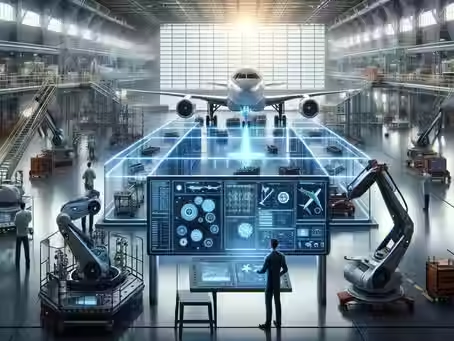

In the aviation industry, Maintenance, Repair, and Overhaul (MRO) operations are the backbone of flight safety and business continuity. Yet, these operations have traditionally been burdened by manual processes, outdated systems, and complex supply chains. As fleets grow and demand for faster turnaround increases, the old methods can no longer keep up.

Enter Artificial Intelligence (AI) and automation — technologies that are transforming the way aviation companies manage maintenance, optimize workflows, and make decisions. The future of MRO management lies in combining human expertise with digital intelligence, creating operations that are not just faster but smarter.

1. Understanding MRO Management in Aviation

1.1 What is MRO Management?

MRO (Maintenance, Repair, and Overhaul) refers to the activities required to ensure that aircraft remain airworthy, safe, and efficient. MRO management involves:

● Scheduling regular inspections

● Managing spare parts inventory

● Handling repairs and overhauls

● Tracking compliance and documentation

In short, MRO is the lifeline of aviation reliability. But with thousands of components, suppliers, and regulations involved, the process is inherently complex.

1.2 The Traditional Challenges

Before AI and automation, MRO management faced several persistent challenges:

● Manual data entry and tracking of work orders

● Limited visibility into part availability and supplier performance

● Slow decision-making due to fragmented data systems

● Inconsistent pricing and quote responses to RFQs

● Human errors leading to compliance or scheduling delays

These inefficiencies led to increased downtime, higher costs, and lost business opportunities.

2. The Digital Transformation of MRO

The aviation industry is experiencing a massive digital transformation, with AI and automation leading the way. These technologies bring precision, predictive power, and process optimization — three elements that redefine how maintenance is done.

2.1 From Manual to Smart Systems

In traditional MRO, technicians and managers relied heavily on paper logs, spreadsheets, and human judgment. Modern AI-powered systems replace guesswork with data-driven insights, automating repetitive tasks and identifying the best decisions in real time.

2.2 The Role of Automation

Automation handles routine operations such as:

● RFQ (Request for Quote) processing

● Work order scheduling

● Inventory reordering

● Report generation This frees human teams to focus on complex maintenance tasks and customer service.

2.3 The Role of Artificial Intelligence

AI takes automation a step further. It doesn’t just execute — it learns. AI systems analyze data, detect patterns, and make intelligent recommendations that continuously improve performance. In MRO management, this means predictive maintenance, dynamic pricing, and optimized repair workflows.

3. How AI is Transforming MRO Operations

3.1 Predictive Maintenance

One of the most powerful uses of AI in MRO is predictive maintenance. By analyzing sensor data and historical maintenance records, AI predicts when a component is likely to fail — allowing maintenance teams to fix issues before they cause downtime.

Benefits include:

● Reduced unplanned outages

● Lower maintenance costs

● Improved aircraft availability

3.2 Intelligent RFQ Processing

AI can automatically read RFQs from incoming emails, extract key information, and respond instantly when enough data is available. This cuts quote response times from hours to seconds, ensuring faster and more accurate customer service.

3.3 Smart Pricing Models

AI analyzes market data, customer history, and competitor pricing to recommend the most profitable yet competitive price for parts or services. This eliminates guesswork and ensures pricing consistency across all channels.

3.4 Automated Data Analysis

Modern MRO systems generate massive amounts of data. AI tools convert this raw data into actionable insights — such as identifying high-performing parts, forecasting demand, or detecting inefficiencies in operations.

3.5 Intelligent Resource Allocation

AI algorithms can schedule maintenance tasks, assign technicians, and allocate resources more effectively. This ensures that every job is completed on time, without bottlenecks or overstaffing.

4. The Power of Automation in MRO Management

While AI handles intelligence and prediction, automation focuses on precision and execution.

4.1 Automated Workflows

From logging a maintenance event to closing a repair order, automation ensures that processes are consistent and error-free. Automated checklists and reminders keep technicians and managers aligned with compliance requirements.

4.2 Inventory and Parts Management

Automated systems monitor stock levels in real time. When inventory drops below a certain threshold, the system automatically reorders parts or flags items nearing expiration.

4.3 Faster Turnaround Times

With automation reducing manual bottlenecks, MRO organizations can complete tasks faster without compromising quality. This directly translates into less aircraft downtime — a critical metric in aviation profitability.

4.4 Workflow Integration

Automation links departments — procurement, maintenance, sales, and finance — through a single digital ecosystem. This integrated view enhances transparency and decision-making across the business.

5. The Synergy Between AI and Automation

AI and automation are powerful on their own, but together, they create a smart ecosystem for MRO management.

Function | AI’s Role | Automation’s Role |

RFQ Processing | Reads and analyzes data | Sends quotes automatically |

Maintenance | Predicts failures | Schedules tasks and alerts |

Pricing | Calculates smart profit margins | Applies approved pricing instantly |

Reporting | Generates insights | Compiles and distributes reports |

Decision-Making | Suggests actions based on analytics | Executes predefined workflows |

This synergy results in end-to-end digital MRO management — where every process is data-driven, efficient, and scalable.

6. The Benefits of AI and Automation for Aviation Businesses

Adopting AI and automation in MRO isn’t just about technology — it’s about business transformation.

6.1 Cost Reduction

Predictive analytics and automated scheduling significantly reduce unplanned maintenance costs and manpower expenses.

6.2 Increased Efficiency

Faster workflows, instant quoting, and real-time inventory updates lead to smoother operations and shorter turnaround times.

6.3 Improved Accuracy

AI eliminates human errors in pricing, scheduling, and reporting, ensuring compliance and reliability.

6.4 Enhanced Profitability

With AI-driven insights, businesses can quote smarter, price better, and win more profitable deals.

6.5 Scalability and Flexibility

Whether a company handles 100 or 10,000 RFQs a day, AI and automation scale effortlessly to match operational needs.

6.6 Customer Satisfaction

Faster responses, consistent pricing, and reliable delivery build stronger relationships with customers and suppliers alike.

7. Real-World Use Cases: AI and Automation in Action

7.1 Automated Quoting Systems

Platforms like AIquote are already transforming how suppliers respond to RFQs. They automatically read emails, calculate prices, and send quotes — cutting manual work and increasing win rates.

7.2 Predictive Maintenance Platforms

AI-powered solutions now monitor aircraft health through sensors, identifying potential issues long before they escalate.

7.3 Digital Twins

A digital twin — a virtual model of an aircraft or system — uses AI to simulate maintenance scenarios and optimize performance.

7.4 Smart Inventory Systems

Automated systems powered by AI can predict part demand and adjust procurement schedules accordingly, reducing waste and overstocking.

8. The Future of MRO Management

The integration of AI and automation is just the beginning. The next phase of MRO innovation will include:

8.1 Full Predictive Ecosystems

MRO systems will become proactive, predicting not only equipment failures but also market shifts, supplier delays, and demand fluctuations.

8.2 Voice and Chat-Based Interfaces

Technicians will interact with AI assistants via voice commands to access manuals, log maintenance data, or request parts — hands-free and in real time.

8.3 Blockchain for Transparency

Combining AI with blockchain will ensure complete traceability of parts and maintenance records, improving compliance and trust.

8.4 Autonomous Maintenance

Robotics and AI will soon enable autonomous inspections and minor repairs, especially for routine tasks like visual checks or sensor replacements.

8.5 Continuous Learning Systems

AI in MRO will evolve constantly, learning from global operations to enhance efficiency across all facilities and fleets.

9. Why Aviation Businesses Should Embrace AI and Automation Now

Every aviation company is under pressure to do more with less — less time, less cost, and less margin for error. AI and automation are no longer optional; they’re strategic necessities.

Companies that adopt these technologies today will:

● Gain a competitive edge through efficiency and accuracy

● Deliver faster responses and higher customer satisfaction

● Operate with greater transparency and control

● Future-proof their business for the next wave of digital aviation

Ignoring the shift could mean falling behind competitors who are already leveraging intelligent systems to outpace traditional operations.

Conclusion: Smart Technology, Smarter Operations

The aviation industry is moving toward a future where AI and automation drive every aspect of MRO management — from predicting part failures to generating quotes in seconds.

By embracing these technologies, MRO businesses can transform their workflows, enhance profitability, and maintain aircraft with unmatched precision.

AI and automation aren’t replacing people — they’re empowering them to focus on strategy, innovation, and growth.

In the fast-paced world of aviation, where every second counts and every decision matters, intelligent MRO management isn’t just an advantage — it’s the future.

Comments