Modern MRO in Aviation: Redefining Aircraft Maintenance for the Digital Era

- Dec 9, 2025

- 6 min read

Updated: Jan 15

The aviation industry operates on a principle that leaves no room for error — safety and reliability come first. Behind every smooth flight and on-time departure lies a complex ecosystem that ensures aircraft remain airworthy, efficient, and compliant with stringent global regulations. This ecosystem is known as Maintenance, Repair, and Overhaul and commonly referred to as MRO.

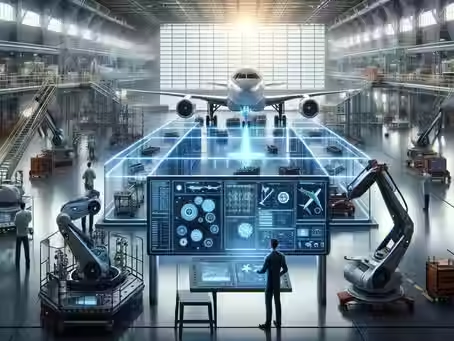

Today’s MRO operations are not what they once were. The integration of advanced technologies, artificial intelligence (AI), and digital quoting platforms like AIquote is transforming the way aviation companies manage aircraft maintenance, procurement, and operational planning. The modern MRO isn’t just about keeping aircraft in the sky; it’s about doing so smarter, faster, and more efficiently.

What Is MRO in the Aviation Industry?

MRO encompasses every process involved in keeping an aircraft safe, serviceable, and ready for operation. It includes preventive inspections, corrective repairs, component replacements, and overhauls — all designed to maintain the performance and reliability of an aircraft throughout its lifecycle.

The MRO sector supports commercial airlines, cargo carriers, private operators, and defense organizations. Without it, aircraft would be grounded indefinitely, and global aviation as we know it would come to a halt.

To understand how it all works, MRO can be divided into three main categories:

● Maintenance: Routine and scheduled inspections that ensure systems and structures are functioning properly.

● Repair: Addressing faults, wear, or unexpected failures that arise during operations.

● Overhaul: A deep restoration process where major components like engines or landing gear are refurbished to like-new condition.

Together, these functions ensure that aircraft not only remain compliant with airworthiness regulations but also operate efficiently — maximizing uptime and minimizing costs.

Why MRO Is the Lifeline of Aviation

The global aviation fleet depends on MRO operations for its very survival. A single unscheduled failure can lead to Aircraft on Ground (AOG) scenarios, costing airlines thousands of dollars per hour. Effective maintenance strategies prevent these costly downtimes while protecting passenger safety and maintaining regulatory compliance.

Moreover, with the increasing age of many aircraft fleets and global supply chain challenges, the MRO sector has become even more critical. Operators are focusing heavily on predictive maintenance, inventory optimization, and AI-powered RFQ management to stay competitive in a fast-changing market.

The Core Components of Aircraft MRO

To understand the complexity of MRO operations, it’s helpful to look at its core functions in detail.

1. Scheduled Maintenance

Scheduled maintenance is preventive and occurs at fixed intervals based on flight hours, cycles, or calendar time. These activities include detailed inspections, lubrication, calibration, and system testing. The goal is simple: prevent potential failures before they happen.

Airlines rely on these checks to maintain regulatory compliance and extend the lifespan of their aircraft. Tasks range from light daily checks to comprehensive D-checks, which can take weeks and involve disassembling significant portions of the aircraft.

2. Unscheduled Maintenance

Unscheduled maintenance occurs when unexpected faults or system failures appear. These situations demand fast response times, precision diagnostics, and access to the right parts — immediately.

For example, a faulty avionics module or hydraulic pump can ground an aircraft, disrupting schedules and causing major financial losses. MRO teams must act quickly, often relying on automated quoting and sourcing platforms like AIquote to find certified replacement parts and suppliers in record time.

3. Directives and Bulletins

Manufacturers as well as the Federal Aviation Administration and similar organizations in other countries, publish directives to assure or enhance aviation safety. MRO’s incorporate these directives and track them in management systems like LogMRO from LogisticsMRO.

4. Component Replacement and Overhaul

Aircraft parts have strict life limits. Whether it’s an engine blade, landing gear component, or avionics sensor, every item must be replaced or overhauled at specific intervals.

Modern MRO companies maintain vast databases of approved vendors, serviceable used material (USM), and overhaul facilities, ensuring that each part is traceable and compliant with aviation standards such as FAA, EASA, or CAAC regulations.

Automation tools and AI platforms have made it possible to track part lifecycles, generate RFQs, and manage supplier responses far more efficiently than ever before.

Empowering Technicians and Engineers

At the heart of MRO operations are Aircraft Maintenance Technicians (AMTs) — skilled professionals responsible for performing inspections, interpreting complex technical data, and ensuring every repair aligns with strict aviation standards.

Today, these technicians are no longer limited to manual inspections or paper-based logs. They now rely on digital maintenance systems, AI-powered diagnostic tools, and real-time data analytics to make faster, more accurate decisions.

Technicians use advanced software to access technical manuals, record maintenance actions, and generate compliance reports instantly. This shift from manual recordkeeping to digital management enhances efficiency, improves traceability, and reduces human error — creating a safer, smarter maintenance ecosystem.

Digital Transformation: The Rise of Smart MRO

The aviation maintenance landscape is undergoing a digital revolution. Cloud-based software, predictive analytics, and AI integration are redefining how maintenance is planned and executed.

Here’s how digital transformation is reshaping MRO operations:

● Predictive Maintenance: Sensors installed on aircraft components send real-time data to predictive models, which can identify potential failures before they occur.

● Automation and AI Integration: Platforms like AIquote automate repetitive processes such as generating and comparing RFQs, helping procurement teams save time and reduce costs.

● Mobile Accessibility: Technicians can access manuals, maintenance logs, and digital workflows directly from tablets or smartphones.

● Paperless Compliance: Automated documentation ensures all actions are traceable and compliant with international aviation standards.

This digital ecosystem allows airlines and MRO providers to increase fleet availability, lower operational costs, and ensure aircraft remain flight-ready at all times.

AIquote: A Game-Changer for Aviation MRO Procurement

In a sector where speed and accuracy can define success, AIquote has emerged as a revolutionary tool for aviation MRO operations. Traditional quoting and procurement workflows often involve countless emails, manual RFQs, and time-consuming price comparisons.

AIquote simplifies this process through automation and artificial intelligence, offering features such as:

● Instant RFQ Handling: Automatically generates, organizes, and prioritizes quotes from multiple suppliers in minutes.

● Smart Comparison Tools: AIquote evaluates quotes based on cost, lead time, and supplier reliability, ensuring the best possible selection.

● Predictive Sourcing: The platform intelligently recommends alternative parts or vendors if primary suppliers are out of stock, helping prevent AOG situations.

● Seamless Integration: AIquote integrates easily with existing MRO or ERP systems, creating a smooth and transparent procurement process.

By eliminating manual tasks and speeding up part acquisition, AIquote empowers MRO providers, airlines, and operators to make data-driven decisions, enhance profitability, and ensure faster aircraft turnaround times.

Simply put, AIquote doesn’t just simplify quoting — it transforms the way MRO teams operate.

The Role of ERP Systems and Aviation Software

Modern MRO facilities rely heavily on integrated ERP (Enterprise Resource Planning) systems that manage everything from work orders and inventory to compliance tracking. These systems provide full visibility into every maintenance task, allowing teams to track performance, monitor costs, and ensure adherence to regulatory requirements.

When integrated with AI-driven tools like AIquote, ERP systems can take MRO efficiency to the next level — connecting maintenance planning directly with procurement automation.

This integration ensures that when a part reaches its service limit, an RFQ can be automatically generated, suppliers compared, and purchase orders processed — all with minimal human intervention.

Choosing the Right MRO Software for Your Organization

Selecting the right maintenance management platform is a critical decision for any aviation business. The software should not only improve operational efficiency but also adapt to the specific regulatory and logistical challenges of aviation maintenance.

When evaluating MRO software or ERP platforms, organizations should ask:

Does it integrate seamlessly with quoting and procurement platforms like AIquote?

Is it scalable across multiple aircraft types or fleet sizes?

Does it provide real-time visibility into inventory and work orders?

Can it handle compliance documentation automatically?

Does it use predictive analytics to reduce unscheduled maintenance events?

Choosing a system that answers “yes” to these questions ensures your organization is ready for the future of aviation maintenance — one that’s digital, data-driven, and AI-empowered.

The Future of MRO: Smarter, Faster, and More Sustainable

The global MRO industry is projected to exceed $110 billion by 2030, driven by the increasing complexity of modern aircraft and the demand for faster, more reliable maintenance. However, the next frontier for MRO will be smart automation,

sustainability, and AI integration.

Emerging trends include:

● AI-Powered Predictive Maintenance: Leveraging machine learning to forecast part failures before they occur.

● Sustainable MRO Practices: Recycling components, reducing waste, and embracing eco-friendly repair processes.

● Blockchain for Traceability: Ensuring transparent and tamper-proof records of part history and certification.

● Global Collaboration Platforms: Cloud-based tools that connect MROs, OEMs, and operators in real time for streamlined workflows.

As MRO operations continue to evolve, AIquote will play a crucial role in helping aviation businesses adapt to these shifts — simplifying RFQ management, improving supplier visibility, and supporting intelligent decision-making across the entire maintenance lifecycle.

Conclusion

The aviation MRO industry stands at the crossroads of tradition and transformation. While its core mission — keeping aircraft safe and operational — remains unchanged, the methods to achieve it have advanced dramatically.

From digital work orders and predictive maintenance to automated RFQs powered by AIquote, the industry is embracing a new era of efficiency, transparency, and innovation.

For airlines, operators, and MRO service providers, success in this evolving landscape depends on one thing: the ability to integrate technology intelligently. By adopting tools like AIquote and next-generation MRO software, organizations can ensure that their maintenance processes are not just compliant — but competitive.

The future of MRO is digital, data-driven, and automated — and AIquote is helping the aviation world get there, one smart quote at a time.

Comments