Understanding How MRO Software Improves Aircraft Maintenance Efficiency

- Dec 9, 2025

- 6 min read

Updated: Jan 15

Introduction: The Aviation Industry’s Need for Smart Maintenance

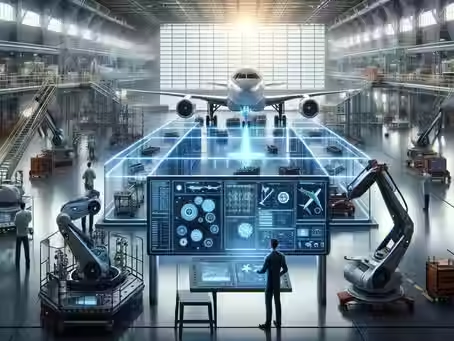

In aviation, safety and efficiency are inseparable. Every flight that takes off depends on a complex ecosystem of maintenance activities, inspections, and regulatory compliance — all managed under the umbrella of MRO (Maintenance, Repair, and Overhaul) operations. However, with increasing fleet sizes, evolving technologies, and tighter schedules, traditional maintenance management methods often struggle to keep up.

This is where MRO software comes in. It serves as the digital backbone of modern aviation maintenance — helping organizations streamline operations, reduce downtime, and ensure absolute compliance with safety regulations.

In this article, we’ll explore how MRO software improves aircraft maintenance efficiency, the features that make it indispensable, and why it has become an essential tool for aviation businesses aiming to stay competitive in a data-driven world. There are many options when it comes to MRO software amongst them: RAMCO, MaintainX, LogMRO, AMOS, Trax

1. What Is MRO Software in Aviation?

MRO software is a specialized digital solution designed to manage, track, and optimize all aspects of aircraft maintenance operations. From scheduling inspections to managing spare parts and ensuring regulatory compliance, it provides a centralized platform where every activity is planned, monitored, and documented.

In simple terms, MRO software replaces manual processes and fragmented systems with intelligent automation and real-time data insights.

Key Functions of MRO Software Include:

● Maintenance planning and scheduling

● Work order and task management

● Parts inventory and procurement tracking

● Regulatory and compliance management

● Digital record-keeping and documentation

● Real-time data analytics and reporting

2. The Challenges of Traditional Maintenance Management

Before the rise of MRO software, aviation maintenance was largely managed through manual spreadsheets, paper logs, and isolated systems. While these methods worked in smaller operations, they became inefficient and error-prone as organizations scaled up.

Here are the key challenges traditional maintenance teams face:

2.1 Manual Record-Keeping

Paper-based documentation is time-consuming and prone to human error. Missing or misplaced records can lead to compliance violations or maintenance delays.

2.2 Limited Visibility

Without centralized data, maintenance teams lack real-time insight into aircraft health, part availability, and ongoing repair tasks.

2.3 Delayed Decision-Making

When information is spread across departments or systems, it takes longer to make operational decisions, affecting aircraft turnaround times.

2.4 High Maintenance Costs

Inefficient processes often lead to overstocking parts, unnecessary repairs, and higher labor costs.

2.5 Compliance Risks

The aviation industry is heavily regulated. Managing documentation manually increases the risk of missed audits or non-compliance with aviation authorities.

To address these pain points, modern MRO software provides an integrated and intelligent solution that connects every aspect of maintenance operations.

3. How MRO Software Transforms Aircraft Maintenance

The true power of MRO software lies in its ability to automate, organize, and analyze every process — from maintenance scheduling to inventory management. Let’s look at the core areas where it improves efficiency.

3.1 Streamlined Maintenance Scheduling

Every aircraft follows a strict maintenance schedule, including routine checks (A, B, C, and D checks) and unscheduled repairs. MRO software automates this scheduling process.

How it helps:

● Automatically generates maintenance tasks based on flight hours, cycles, or calendar intervals.

● Prevents scheduling conflicts by optimizing hangar and technician availability.

● Provides real-time updates to all stakeholders.

With automation, maintenance managers can eliminate bottlenecks and ensure that aircraft spend more time flying and less time grounded.

3.2 Centralized Data Management

One of the biggest advantages of MRO software is data centralization. Instead of maintaining information across multiple spreadsheets or systems, everything — from maintenance logs to part numbers — resides in one secure database.

Benefits include:

● Easier data retrieval during inspections or audits.

● Seamless collaboration between departments.

● Reduced duplication and improved data accuracy.

In short, centralized data helps maintenance teams make faster and better-informed decisions.

3.3 Real-Time Aircraft Health Monitoring

Modern MRO platforms can integrate with sensors and aircraft systems to gather live operational data. This enables predictive maintenance — identifying potential issues before they cause breakdowns.

For example: If an engine component shows unusual vibration levels, the MRO system automatically flags it for inspection before failure occurs.

The result:

● Reduced unplanned downtime

● Lower repair costs

● Improved aircraft reliability

This predictive capability marks a major shift from reactive to proactive maintenance management.

3.4 Improved Inventory and Parts Management

Aircraft maintenance relies heavily on spare parts and consumables. Delays in parts availability can ground an aircraft and cause financial loss. MRO software simplifies inventory management by keeping real-time track of stock levels, suppliers, and procurement cycles.

Key advantages:

● Automatic reordering of parts before they run out.

● Integration with vendor databases for quick procurement.

● Reduced overstocking and waste.

● Full traceability of every part’s lifecycle.

This ensures that maintenance teams always have the right part, at the right time, without over-investing in inventory.

3.5 Enhanced Compliance and Documentation

Compliance is one of the most critical aspects of aviation maintenance. MRO software helps ensure that every maintenance task, inspection, and part replacement meets the regulatory standards set by authorities like FAA, EASA, or CAAC.

How it improves compliance:

● Maintains digital audit trails.

● Tracks technician certifications and authorizations.

● Automatically generates compliance reports.

● Alerts managers about upcoming inspections or certificate renewals.

This not only simplifies audits but also ensures 100% traceability and transparency across all operations.

3.6 Labor and Resource Optimization

Managing human resources effectively is essential for operational efficiency. MRO software allows managers to:

● Assign tasks based on skill levels and certifications.

● Track work progress and performance in real-time.

● Prevent overbooking or underutilization of technicians.

With these tools, organizations can maximize workforce efficiency while maintaining high-quality standards.

4. Key Features That Drive Efficiency in MRO Software

Different MRO solutions may vary in their capabilities, but the most effective systems share common features designed to drive efficiency:

Feature | Purpose |

Automated Workflows | Reduces manual input and human error. |

Predictive Maintenance Tools | Uses data analytics to forecast maintenance needs. |

Cloud-Based Access | Enables teams to access data from anywhere. |

Integrated Analytics Dashboards | Offers real-time insights into performance metrics. |

Document Control | Ensures proper versioning and compliance tracking. |

Third-Party Integrations | Connects with ERP, CRM, and inventory management systems. |

Each feature works together to create a connected ecosystem, ensuring that no maintenance task or compliance requirements slip through the cracks.

5. The Measurable Impact of MRO Software on Efficiency

Let’s look at how MRO software directly impacts key performance metrics in aviation operations:

5.1 Reduced Aircraft Downtime

Automated scheduling and predictive alerts minimize unscheduled ground time, keeping aircraft operational and profitable.

5.2 Faster Turnaround Times

Technicians receive digital work orders instantly, ensuring quick task completion without waiting for manual instructions.

5.3 Better Cost Control

Real-time visibility into parts usage and labor hours allows managers to identify cost-saving opportunities.

5.4 Higher Data Accuracy

By eliminating manual entry, MRO software ensures data integrity — critical for audits and decision-making.

5.5 Enhanced Profitability

More uptime, better resource management, and lower maintenance costs lead directly to improved profit margins.

6. Integration of Artificial Intelligence in MRO Software

As technology evolves, modern MRO platforms are integrating artificial intelligence (AI) to further improve performance.

AI-driven MRO software can:

● Analyze historical maintenance data to predict component failures.

● Recommend optimal maintenance schedules.

● Optimize pricing and procurement for spare parts.

● Automate repetitive administrative tasks.

Solutions like AIquote take it a step further by applying AI to quoting and parts management, helping aviation companies streamline their commercial and maintenance workflows simultaneously.

This convergence of AI and MRO software marks the next step in digital transformation for aviation businesses.

7. Choosing the Right MRO Software

Selecting an MRO platform is a strategic decision. Here’s what aviation businesses should consider before implementation:

7.1 Scalability

Ensure the system can handle future expansion — more aircraft, more users, and more data.

7.2 Integration Capability

The software should integrate seamlessly with existing ERP, CRM, and parts management systems.

7.3 Customization

Every operation is unique. Choose a platform that allows configuration based on your workflow.

7.4 Cloud Accessibility

Cloud-based solutions provide flexibility, remote access, and real-time collaboration.

7.5 Vendor Support

Look for providers offering strong onboarding, technical support, and continuous updates.

The right MRO solution should feel like a strategic partner, not just a software purchase.

8. The Future of MRO Software in Aviation

As digital transformation accelerates, the future of MRO software is moving toward full automation and intelligence. We can expect developments like:

● Predictive maintenance through IoT and AI integration

● Blockchain-based maintenance records for tamper-proof compliance

● Augmented reality (AR) tools for virtual inspections

● Cloud-native and mobile-first systems for global accessibility

In the near future, MRO software will not just manage maintenance — it will predict, optimize, and automate it end-to-end.

Conclusion: Efficiency Through Intelligence

Aircraft maintenance is one of the most critical and costly components of aviation operations. Efficiency, accuracy, and compliance can mean the difference between profit and loss.

By adopting MRO software, aviation businesses can transition from reactive, manual workflows to proactive, data-driven operations. The results are clear — reduced downtime, optimized resource use, lower costs, and improved safety.

In short, MRO software doesn’t just enhance maintenance efficiency — it redefines how the aviation industry operates. For organizations aiming to stay competitive in a fast-changing world, embracing this technology isn’t just a smart choice — it’s an essential one.

Comments