What Is MRO in Aviation and Why It’s So Important

- Dec 9, 2025

- 7 min read

Updated: Jan 15

Aviation is one of the most complex and safety-driven industries in the world. Every flight, every part, and every operation depends on precision, reliability, and continuous performance. Behind this precision lies a critical process that keeps aircraft flying safely

— MRO.

MRO stands for Maintenance, Repair, and Overhaul — the backbone of aviation reliability. Without MRO, even the most advanced aircraft would quickly become unsafe and inefficient.

In this article, we’ll explore what MRO means in aviation, how it works, its different types, and why it plays such a vital role in modern aviation businesses.

1. What Does MRO Mean in Aviation?

MRO (Maintenance, Repair, and Overhaul) refers to the processes, systems, and operations responsible for maintaining the airworthiness, performance, and safety of aircraft and their components.

Every aircraft, whether it’s a commercial jet, cargo plane, or private aircraft, must go through continuous MRO activities throughout its lifecycle.

In simpler terms:

MRO ensures that aircraft remain flight-ready, compliant, and efficient — every single day.

2. The Three Core Elements of MRO

MRO isn’t a single process — it’s a structured combination of three essential operations:

1. Maintenance

Routine checks and preventive care carried out at specific intervals.

● Includes line maintenance, daily checks, and minor part replacements.

● Aims to prevent unexpected failures.

2. Repair

The process of fixing or replacing parts that are damaged, worn, or malfunctioning.

● Can involve engines, avionics, hydraulics, or structural components.

● Ensures that aircraft performance is fully restored.

3. Overhaul

A deep inspection and refurbishment of major components such as engines, landing gears, or flight systems.

● Often performed after a specific number of flight hours or cycles.

● Extends the operational life of the aircraft.

Together, these three areas form the foundation of aviation safety and operational reliability.

3. Why Is MRO So Important in Aviation?

Aviation operates in an environment where there’s zero room for error. MRO ensures that every aircraft meets strict regulatory, safety, and performance standards.

Here’s why MRO is indispensable:

1. Safety and Airworthiness

Aircraft safety is directly dependent on proper maintenance. Regular MRO ensures that every system, from engines to avionics, is functioning perfectly before takeoff.

2. Compliance with Aviation Regulations

Authorities like the FAA (Federal Aviation Administration), EASA (European Union Aviation Safety Agency), and others mandate strict MRO schedules. Failure to comply can ground aircraft or result in heavy penalties.

3. Cost Efficiency

Preventive maintenance helps airlines avoid costly breakdowns and emergency repairs, saving millions in operational expenses.

4. Maximizing Aircraft Life

Proper overhaul and component care extend the lifespan of aircraft, allowing operators to get the most out of their investment.

5. Operational Reliability

Consistent MRO processes minimize downtime and ensure that aircraft are ready for scheduled flights.

4. Types of MRO in Aviation

Different levels of maintenance are performed depending on the aircraft’s usage, hours, and condition. Let’s break them down:

1. Line Maintenance

● Performed daily or between flights.

● Includes inspections, tire checks, oil changes, and quick fixes.

● Keeps aircraft ready for immediate operations.

2. Base Maintenance

● Conducted less frequently but involves deeper inspections.

● Takes place in hangars and may last several days.

● Includes detailed structural and system checks.

3. Engine Maintenance

● One of the most critical parts of aviation MRO.

● Involves performance monitoring, repair, and overhauling of aircraft engines.

4. Component Maintenance

● Individual parts like landing gears, hydraulic pumps, and avionics systems are inspected and refurbished separately.

5. Heavy Maintenance (C and D Checks)

● The most detailed inspection level.

● Requires full aircraft disassembly for structural inspection and system overhaul.

● Conducted every few years and can take weeks.

5. The MRO Lifecycle: From Inspection to Return to Service

MRO operations follow a systematic workflow that ensures no task is overlooked.

Step 1: Planning and Scheduling

Maintenance planners analyze flight hours, cycles, and performance data to schedule upcoming checks.

Step 2: Inspection

Technicians perform detailed inspections on airframes, engines, and systems to detect wear or damage.

Step 3: Repair or Replacement

Any defective part is repaired or replaced using certified components.

Step 4: Testing

Systems are tested to ensure functionality and compliance with manufacturer standards.

Step 5: Documentation

Every maintenance action is logged digitally for traceability and audit compliance.

Step 6: Return to Service

Once all checks are passed, the aircraft is cleared for operation and returned to active service.

6. How MRO Supports Different Aviation Stakeholders

MRO is not limited to airlines. It impacts multiple players across the aviation ecosystem:

1. Airlines

● Manage fleet readiness and safety.

● Use MRO data to optimize flight schedules and reduce downtime.

2. MRO Service Providers

● Perform maintenance on behalf of airlines or operators.

● Offer specialized repair and overhaul services.

3. Aircraft Manufacturers (OEMs)

● Provide maintenance guidelines and component support.

● Work closely with MRO providers for technical updates.

4. Parts Suppliers and Distributors

● Support MRO operations by providing certified components quickly and accurately.

● Platforms like AIquote automate quoting and parts pricing for faster supply chain response.

5. Regulatory Authorities

● Audit MRO processes to ensure compliance with safety and performance standards.

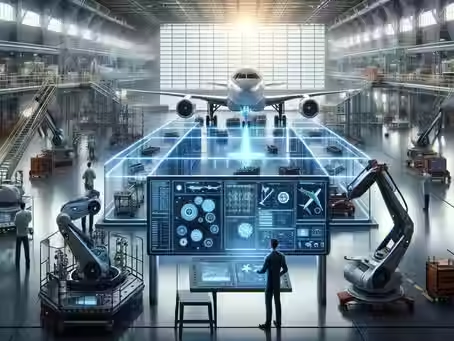

7. The Role of Technology in Modern MRO

The aviation MRO industry has evolved dramatically with the rise of digital transformation and AI-based tools.

1. MRO Software Solutions

Modern MRO management systems help automate:

● Work orders

● Inventory control

● Compliance documentation

● Labor scheduling

● Performance analytics

This centralization eliminates manual errors and improves efficiency.

2. Artificial Intelligence (AI) and Machine Learning

AI-driven platforms analyze flight and maintenance data to predict potential failures before they occur. This concept — predictive maintenance — reduces downtime and costs dramatically.

3. Automation in Quoting and Parts Procurement

AI-based tools like AIquote automatically process RFQs (Requests for Quotes), calculate best prices, and send quotes instantly — making MRO procurement faster and more profitable.

4. IoT and Real-Time Monitoring

Sensors on aircraft continuously collect performance data, allowing for remote monitoring and condition-based maintenance.

5. Cloud and Mobile Access

Cloud-based MRO platforms give global teams real-time access to maintenance data from anywhere.

8. Benefits of a Strong MRO Strategy

A well-implemented MRO strategy delivers measurable improvements across all areas of aviation operations.

1. Improved Fleet Performance

Regular checks and predictive insights keep aircraft operating at peak performance.

2. Enhanced Safety

Strict maintenance cycles drastically reduce the risk of mechanical failures or in-flight issues.

3. Reduced Downtime

Efficient planning ensures aircraft spend less time grounded and more time in the air.

4. Better Inventory Management

Digital tools prevent shortages or overstocking by tracking real-time part usage.

5. Increased Profitability

By optimizing maintenance and procurement, businesses save time, reduce waste, and increase margins.

6. Streamlined Compliance

Automated documentation ensures effortless audits and regulatory approvals.

9. Challenges Faced by Aviation MRO Industry

Despite its importance, MRO operations face significant challenges that technology is now helping to solve:

● Data Overload: Managing data from thousands of aircraft components.

● Regulatory Pressure: Keeping up with evolving aviation laws and certifications.

● Skill Shortage: Finding skilled technicians and engineers.

● High Costs: Managing expensive parts and maintenance logistics.

● Coordination Issues: Aligning airlines, suppliers, and MRO facilities efficiently.

Solutions like digital MRO systems and AIquote integration are helping organizations overcome these issues with automation and intelligence.

10. Global Market Outlook for Aviation MRO

The global MRO market is one of the largest segments in aviation — and it’s growing rapidly.

According to industry forecasts:

● The global aviation MRO market is expected to exceed $120 billion by 2030.

● Engine and component maintenance will account for nearly 60% of the total spend.

● Digital MRO solutions will lead the growth, offering cost savings and operational transparency.

The demand for smarter, AI-driven maintenance tools is pushing the industry toward greater efficiency and automation.

11. MRO and the Future of Aviation

The future of MRO is predictive, data-driven, and automated. Here’s what’s coming next:

1. Predictive Analytics

AI will continue to evolve, predicting failures before they happen and recommending optimal maintenance schedules.

2. Blockchain in MRO

Blockchain technology will enhance transparency and traceability for aircraft parts and repair histories.

3. Digital Twins

Virtual replicas of aircraft components will simulate wear and tear — allowing engineers to test scenarios before implementing real repairs.

4. Sustainability in Maintenance

Green aviation is on the rise, and MRO will play a major role in reducing waste and optimizing fuel efficiency through smarter maintenance.

5. Integration with AI-Powered Platforms

Solutions like AIquote and LogisticsMRO will bring automation not just to maintenance, but also to parts procurement, quoting, and sales operations — creating an end-to-end intelligent ecosystem.

12. The Human Factor in MRO

While automation is revolutionizing aviation maintenance, skilled professionals remain at the heart of MRO operations. Technicians, engineers, and inspectors bring the human expertise that technology supports — not replaces.

Key Skills for Modern MRO Professionals

● Deep technical knowledge of aircraft systems.

● Understanding of digital tools and MRO software.

● Strong analytical and safety compliance mindset.

Combining human expertise with digital intelligence is what truly defines successful MRO in the modern aviation era.

13. Conclusion: MRO – The Lifeline of Aviation

Without MRO, aviation would not exist as we know it. Every safe takeoff, every smooth landing, and every efficient flight depends on the unseen but powerful work of maintenance and repair teams.

From airlines and OEMs to suppliers and AI-based platforms like AIquote, the MRO ecosystem ensures that aviation stays reliable, efficient, and profitable.

In the modern world of automation and artificial intelligence, MRO is no longer just a technical process — it’s a strategic advantage. It keeps fleets flying, costs under control, and safety uncompromised.

Final Thought

As aviation technology continues to advance, MRO will evolve from routine maintenance to intelligent, predictive operations powered by AI and data.

Businesses that embrace this transformation — integrating digital MRO systems and AI-based solutions — will lead the future of aviation. Because in the sky, precision isn’t optional — it’s everything.

Comments