What Is MRO Software? A Complete Guide for Aviation Businesses

- Dec 9, 2025

- 6 min read

Updated: Jan 15

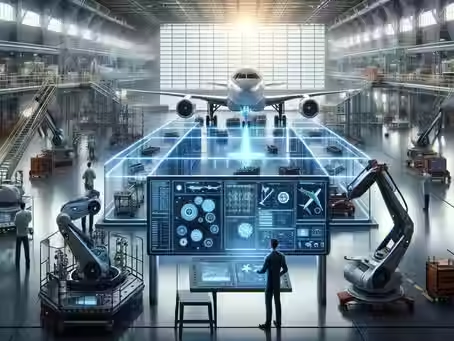

In the highly technical and regulated world of aviation, maintenance operations are the foundation of safety, performance, and profitability. Every aircraft component,

inspection, and repair must be managed with precision — and that’s where MRO software comes into play.

From airlines and MRO (Maintenance, Repair, and Overhaul) organizations to parts suppliers and OEMs, MRO software has become the digital backbone of modern aviation maintenance.

This article provides a complete guide to what MRO software is, how it works, its core features, and how it is transforming aviation businesses around the world.

1. Understanding the Concept of MRO in Aviation

Before diving into MRO software, it’s essential to understand what MRO really means.

What Is MRO?

MRO stands for Maintenance, Repair, and Overhaul. It refers to all the activities required to keep an aircraft airworthy and operating efficiently.

The Core Functions of MRO Include:

● Maintenance: Regular checks, servicing, and preventive actions to avoid breakdowns.

● Repair: Fixing or replacing damaged parts to restore functionality.

● Overhaul: Comprehensive restoration of aircraft components to extend their life cycle.

These processes are complex, data-heavy, and strictly regulated. Managing them manually or through spreadsheets can lead to costly mistakes, downtime, and compliance issues. That’s why the aviation industry has turned to digital tools — MRO Software.

2. What Is MRO Software?

MRO software is a digital platform that helps aviation businesses plan, manage, track, and control all aspects of aircraft maintenance and repair operations.

It centralizes every function — from inventory management and work orders to compliance tracking, documentation, and labor management — into one unified system.

Simply put:

MRO software is the brain of aviation maintenance — connecting data, people, and processes to ensure aircraft remain safe, efficient, and operational.

3. Why MRO Software Is Essential for Aviation Businesses

In aviation, time is money, and precision saves lives. Even the smallest delay or data error can ground an aircraft and cost thousands of dollars per hour.

MRO software solves these challenges by:

● Automating manual maintenance tasks.

● Reducing paperwork and human error.

● Tracking every part and inspection in real time.

● Ensuring compliance with airworthiness regulations.

● Optimizing inventory and resource planning.

In short, MRO software gives businesses control, visibility, and confidence in every maintenance operation.

4. How MRO Software Works

MRO software integrates multiple departments — maintenance, engineering, purchasing, logistics, and quality assurance — into one synchronized ecosystem.

Here’s how it functions step by step:

Step 1: Work Order Creation

When an aircraft needs inspection, the system automatically generates a work order with detailed task lists and technician assignments.

Step 2: Resource Allocation

The software assigns available technicians, spare parts, and tools based on availability and skill set.

Step 3: Task Tracking

Each maintenance task is logged, timed, and tracked in real time for accountability and progress visibility.

Step 4: Quality and Compliance Checks

All actions are automatically documented to ensure compliance with aviation authorities such as FAA, EASA, or CAA.

Step 5: Reporting and Analytics

Finally, the software compiles data into dashboards and reports to help management make data-driven decisions.

5. Core Features of MRO Software

The best MRO software platforms offer a robust suite of features designed to streamline operations from start to finish.

1. Work Order Management

Create, assign, and track maintenance tasks across aircraft, components, or systems with full visibility.

2. Inventory and Parts Management

Monitor parts usage, location, shelf life, and reorder levels to prevent stockouts and overstocking.

3. Maintenance Scheduling

Plan preventive and predictive maintenance to reduce unscheduled downtime.

4. Documentation and Compliance

Automatically maintain records, manuals, and certifications to meet regulatory standards.

5. Labor and Resource Tracking

Track technician performance, working hours, and certifications to ensure proper resource utilization.

6. Procurement and Vendor Management

Simplify purchasing, vendor communication, and part sourcing — ensuring fast turnaround and accurate pricing.

7. Real-Time Dashboards

Gain insights into fleet status, maintenance progress, and cost performance from one control panel.

8. Integration Capabilities

Connect with ERP systems, quoting platforms like AIquote, and digital inventory databases for unified operations.

9. Mobile Accessibility

Allow field technicians to access and update work orders directly from mobile devices — improving speed and accuracy.

6. The Business Benefits of MRO Software

Implementing MRO software goes far beyond efficiency — it transforms how aviation businesses operate.

1. Improved Efficiency

Automates repetitive tasks, saving time and reducing manual errors.

2. Cost Control

Tracks all maintenance-related costs, helping management optimize budgets and reduce waste.

3. Enhanced Compliance

Ensures documentation meets regulatory and audit requirements automatically.

4. Predictive Maintenance

Leverages analytics to forecast when components may fail — enabling proactive repairs.

5. Increased Aircraft Availability

Reduces downtime by optimizing scheduling and inventory readiness.

6. Better Decision-Making

Provides real-time visibility into every maintenance activity and cost.

7. Streamlined Collaboration

Connects all departments under one digital platform, enhancing communication and coordination.

7. Who Uses MRO Software?

MRO software is essential across multiple segments of the aviation ecosystem.

1. Airlines

To manage fleet maintenance, schedules, and regulatory compliance.

2. Independent MRO Providers

To handle customer aircraft, parts procurement, and labor management efficiently.

3. OEMs (Original Equipment Manufacturers)

To track component life cycles and warranty management.

4. Parts Distributors and Suppliers

To monitor inventory, quotes, and customer service workflows.

5. Government and Defense Organizations

For managing military fleet maintenance with maximum traceability and control.

8. The Role of AI and Automation in Modern MRO Software

Today’s leading MRO platforms are powered by artificial intelligence (AI) and automation, enabling them to predict, recommend, and optimize.

AI Capabilities in MRO Software Include:

● Predicting component failure using historical data.

● Suggesting optimal maintenance schedules.

● Automating repetitive administrative tasks.

● Detecting anomalies in maintenance logs.

● Supporting AI-based quoting tools like AIquote to respond faster to part requests.

This evolution means MRO software is no longer a database — it’s an intelligent system that thinks and learns from operations.

9. Integration with Quoting and Supply Chain Systems

MRO software doesn’t operate in isolation. To achieve complete operational harmony, it integrates with:

● AI-based quoting platforms (like AIquote)

● ERP and accounting systems

● Inventory management tools

● Procurement and vendor systems

● Document management systems

This integration ensures that when a part is required, it can be quoted, sourced, and approved automatically — reducing turnaround time dramatically.

10. Key Trends in MRO Software Development

The aviation maintenance industry is evolving rapidly, and MRO software is at the center of this change. Here are the most impactful trends shaping its future:

1. Predictive Maintenance

AI analyzes sensor data to predict potential failures before they happen.

2. Cloud-Based Platforms

Cloud MRO software offers flexibility, scalability, and remote access from anywhere in the world.

3. Blockchain for Traceability

Some solutions are integrating blockchain to ensure secure and transparent part tracking.

4. Mobile-First Design

Technicians can now manage inspections, update logs, and capture images directly from mobile apps.

5. Data-Driven Decision Support

Advanced analytics dashboards empower managers to make smarter, faster decisions.

11. The Difference Between Traditional and Modern MRO Software

Traditional MRO Tools | Modern AI-Powered MRO Software |

Manual data entry | Automated data capture |

Limited visibility | Real-time dashboards |

Reactive maintenance | Predictive maintenance |

Complex paperwork | Digital documentation |

No integration | Full system integration |

Modern solutions like those integrated with AIquote and LogisticsMRO are transforming aviation maintenance from reactive to intelligent and proactive operations.

12. Challenges MRO Software Solves

Aviation maintenance involves thousands of moving parts — literally and digitally. MRO software tackles major operational pain points such as:

● Disconnected systems and data silos

● Missed inspections and poor scheduling

● Manual errors in part tracking

● Uncontrolled maintenance costs

● Difficulty meeting compliance audits

● Lack of performance visibility

With digital automation, these challenges become manageable, measurable, and improvable.

13. How to Choose the Right MRO Software

Selecting an MRO system is a strategic decision. Here’s what to look for:

Industry Specialization — Choose software built specifically for aviation.

Scalability — Ensure it grows with your business.

Integration Capability — Must connect with ERP, inventory, and quoting tools like AIquote.

Compliance Support — Should meet global aviation standards.

User Experience — Simple, intuitive interfaces boost adoption.

Support and Training — Reliable onboarding and technical assistance are crucial.

14. The Future of MRO Software

The future of aviation maintenance is digital, data-driven, and AI-powered. We’re moving toward a world where:

● Maintenance schedules are optimized by AI.

● Parts are ordered automatically before they’re needed.

● Real-time dashboards track aircraft health globally.

● Digital twins simulate performance to prevent issues.

MRO software will be the foundation of this transformation — connecting engineering, logistics, and technology into one intelligent ecosystem.

15. Conclusion: The Heart of Aviation Maintenance

In modern aviation, MRO software is not a luxury — it’s a necessity. It ensures safety, compliance, and operational excellence while enabling faster, smarter decision-making.

Whether you’re an airline, MRO provider, or parts supplier, investing in an advanced MRO platform is the key to future-proofing your operations.

And when integrated with AIquote, MRO software becomes even more powerful — combining maintenance intelligence with automated quoting efficiency to deliver a complete aviation management solution.

Final Thought

The aviation industry thrives on precision, and MRO software provides just that — precision in maintenance, data, and decision-making. It’s not just software; it’s the digital cockpit of your maintenance operation — guiding you toward a safer, more efficient, and more profitable future.

Comments